Compliance

The B-70 burners comply with the European Directives:

- About machines, 2006/42/EK directive

- About electromagnetic compatibility, 2014/30/EK directive

- About low voltage, 2014/35/EK directive

Description of burner

The B-70 burner is a excessively versatile equipment. For example in new generation boilers, on bread oven furnace, in hot air generator, and on renewed boilers. It is includes round burner head, a primary ventilator (more speed level), a flame sensor - igniter, an internal screw. When compressed air is connected self-cleaning system operates. The fuel is supplied by a flexible tube from the pellet tank.

The microprocessor control panel manages the burner and the all equipment and there is possible to set time terms.

Security equipment

- Burner safety thermostat (to prevent backfire)

- Firecut valve (opcional) (to prevent backfire)

|

Description

|

Unit

|

B-Max 70 kW

|

|

Burner output

|

kW

|

70

|

|

Electrical connection

|

V~Hz

|

230~50

|

|

Average energy consumption

|

W

|

60

|

|

Ignition

|

W

|

170

|

|

Fuse (delayed)

|

A

|

3,15

|

|

Noise level

|

dBA

|

40

|

|

Fire length

|

mm

|

350

|

|

Min combustion chamber (height)

|

mm

|

450

|

|

Min combustion chamber (width)

|

mm

|

560

|

|

Min combustion chamber (depth)

|

mm

|

650

|

|

Smoke flue demand drafts

|

Pa

|

30

|

|

Weight (with screw feeder)

|

kg

|

33

|

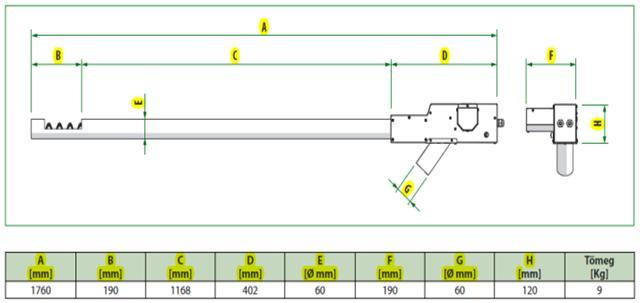

Screw feeder sizes:

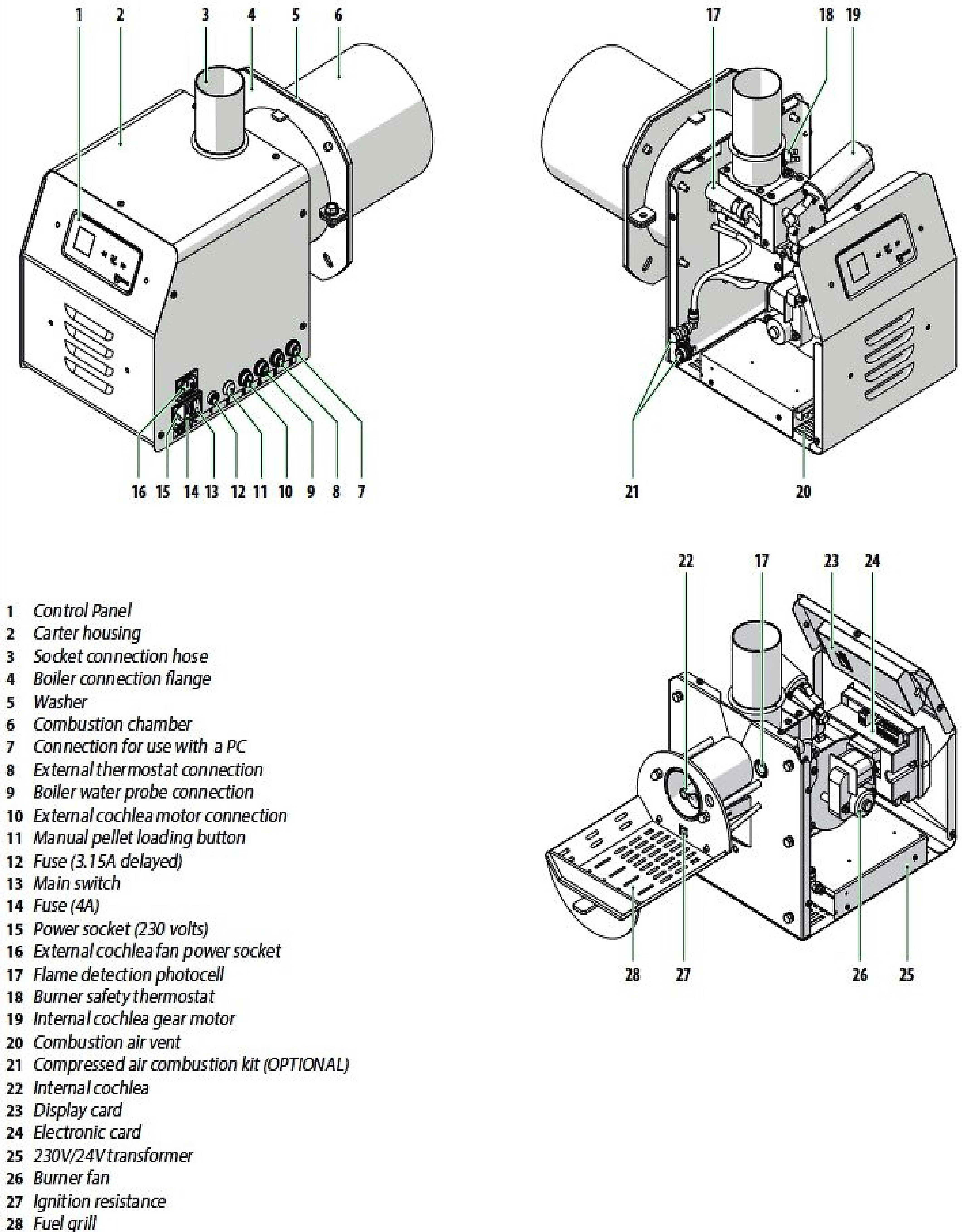

Burner parts:

Operation

The microprocessor control panel manages the all equipment, which programs the next phases:

- Starts an ignition process in case of heat demand: the main ventilator starts on the ignition turn, the exteral and internal screw supply the pellet which needs the ignition. Operation time of internal screw is longer 8 seconds than the external.

- When finishes the pellet infusing what needs the ignition the ignition resistance turns on which it burns the pellet. The flame sensor perceives the brightness of the resulting flame (Safety time is max 20 minutes). If the ignition is failed the burner stops. In the case of BLOCK STOPPING, to reset normal operating conditions, disconnect the equipment, check the cause of malfunction and re-energize the unit.

- After detecting the appropriate brightness, the unit starts normal operation, the output power is continuously increased up to the set maximum value; then operation continues in modulation mode until the boiler or DHW storage temperature reaches the set value. The outer and inner bolts during the operation of the burner ensure the amount of pellet dosing corresponding to the set performance.

- When the set temperature is reached, the control stops the internal and external augers and uses the fan to burn the pellets remaining in the combustion chamber.

- When the light intensity drops below 20Lux in the combustion chamber, the fan increases its speed to clean the combustion chamber from the last residues and stops the combustion process.

The burner is now ready for the next start.

Pellet

The recommended pellet quality:

| Description |

Unit |

Pellet |

| Diameter |

mm |

6 (Din Plus) |

| Depth |

mm |

25 (max) |

| Density |

kg/m3 |

650 |

| Lower calorific value |

kWh/kg |

5 |

| Humidity (compared to the weight) |

% |

8 (max) |

| Ash (compared to the weight) |

% |

1 (max) |

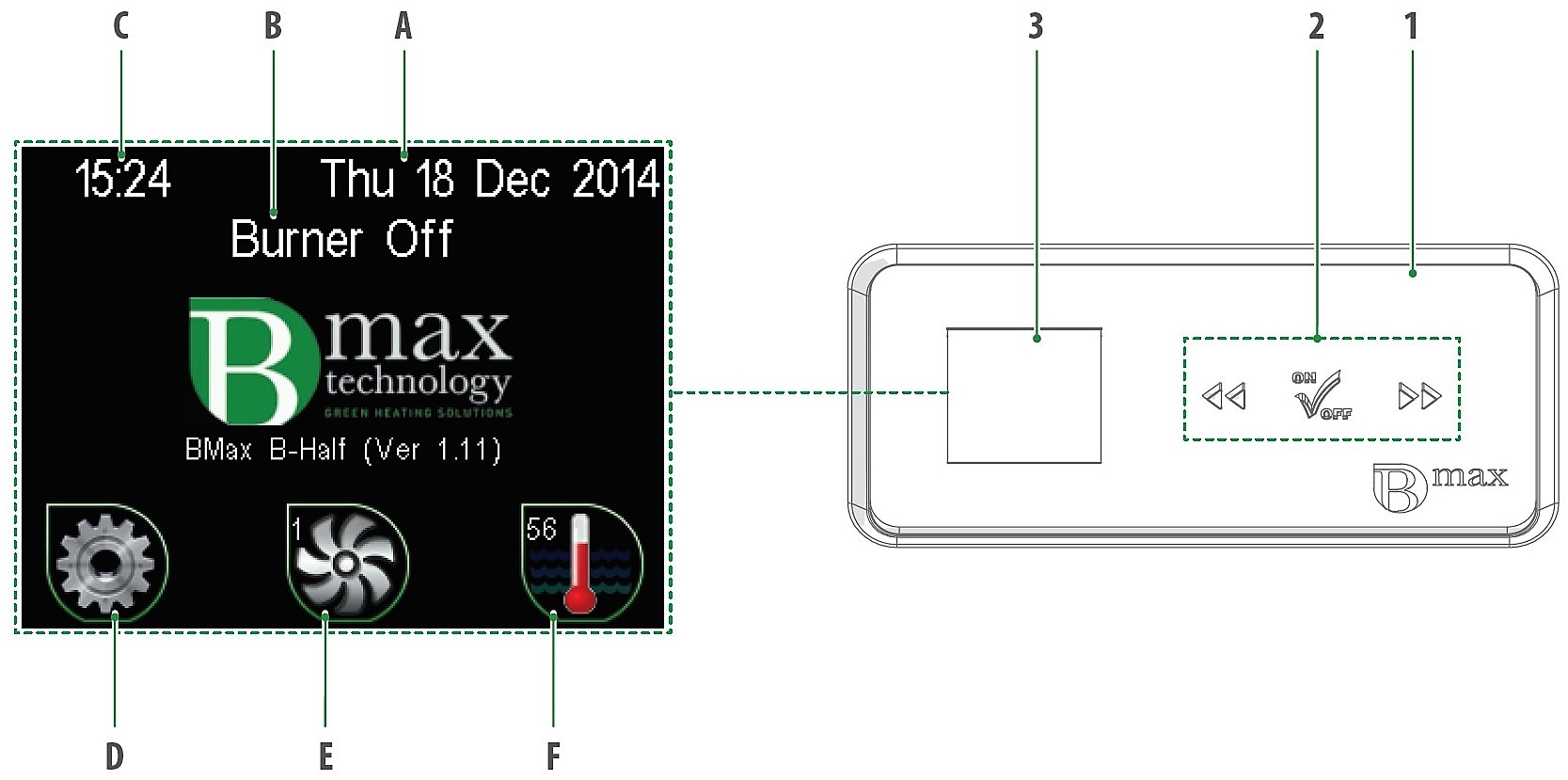

Burner screen:

SCREEN:

- A Date

- B Status of the burner

- C Watch

- D Parameters

- E Power consumption

- F Temperature of the boiler water

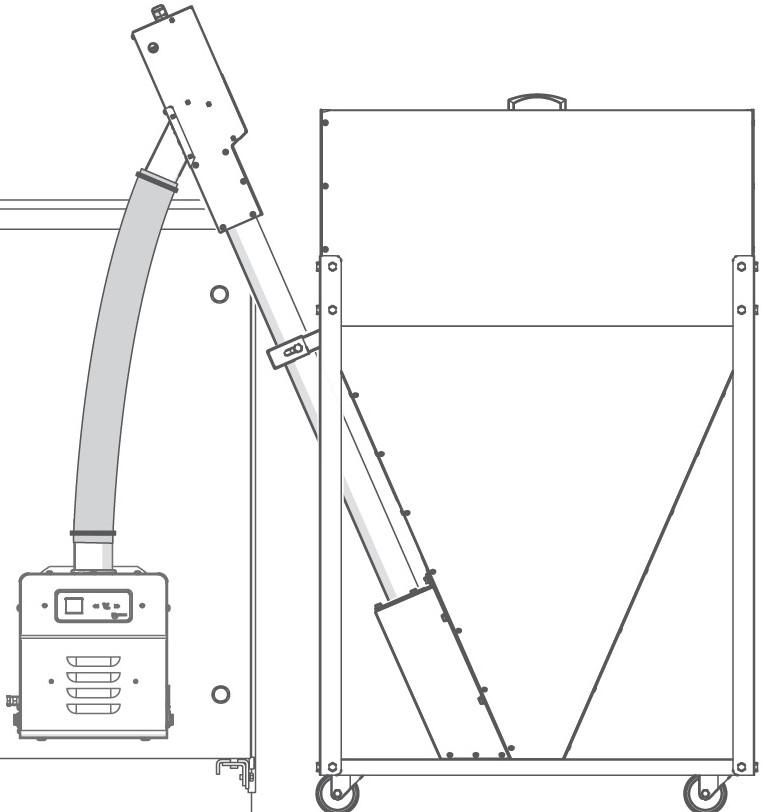

Pellet burner equipment on the boiler: