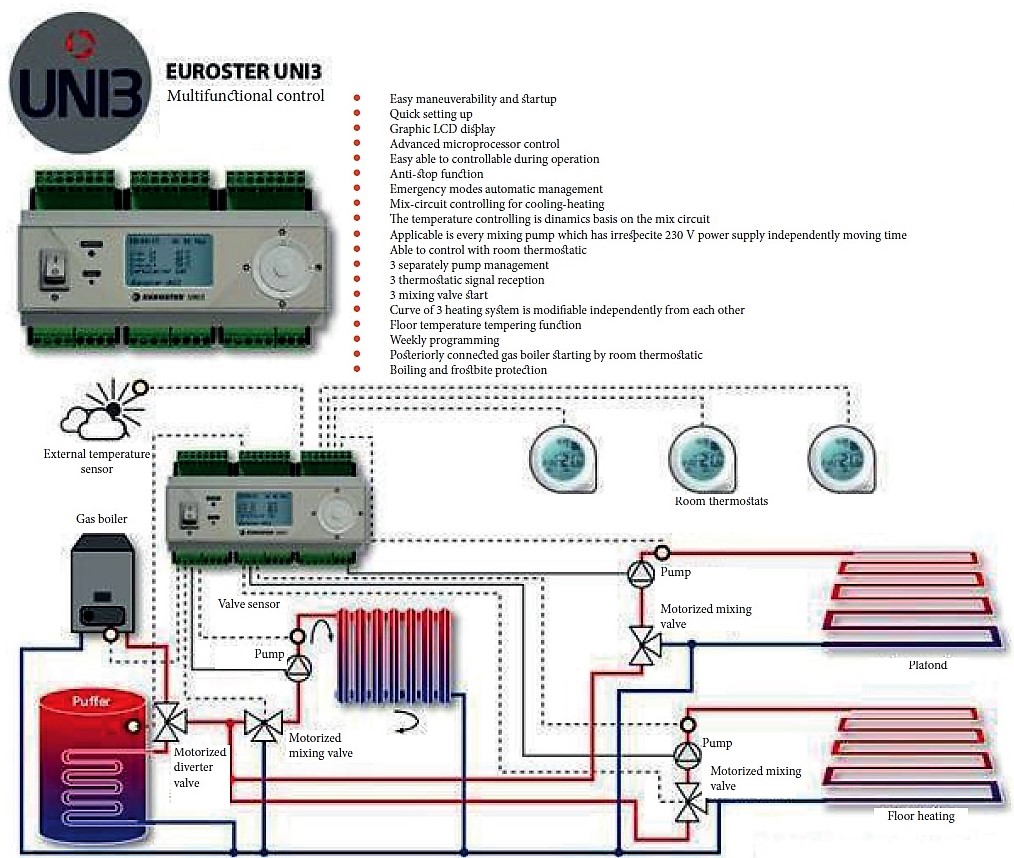

UNI3 controller

The heating system controller is equipped with three separate mixing valve and pump controllers, which can be launched by room thermostat signal and tuned by outer temperature signal. Able to receive three separate thermostat signals which are voltage free. the mixing valves can be controlled to heat and cool by a weekly program.

The Euroster UN13 cooling/heating controller provides two further functions, turn on the domestic hot water pump with a selectable operational mode (primary/secondary). This is programmable on a weekly basis. Furthermore, the controller can launch a circulating pump based on temperature or time mode. Both of these even by weekly programming.

+ automatic fail-safe pump control

+ floor temperation

The heating system controller is able to launch other boilers (ex.: gas boiler).

Thanks to its grapichal display the Euroster UNI3 cooling-heating controller gives precise and wide ranged information about its continous operation, making it lot easier to set and to check the device. The unit also includes anti-freeze function which prevents malfunctions outcoming of the freezing.

Furthermore the controller is useable for buffer tank and boilers, since it has an overheating protection.

During overheating it overrides the signal from the room thermostat.

The controller has wide range of compatibity. It can be easily installed to a new or an existing system. It's basic accessory contains sensors and signallers. Due to its graphical display the Euroster UNI3 controller makes the setup an easy process, which can be started with the revolving command button to the right.

The controller is able to manage three pieces of three or four-way mixing valve.

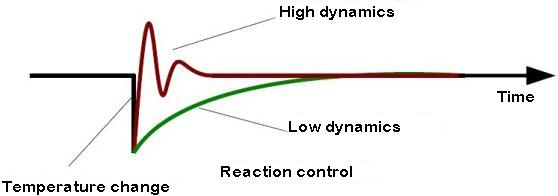

It can be applied to all sorts of mixing valve motors (230 V). The controller manages the mixing valve not time based but thermodinamically. As a result the controller follows the values and opening dinamics we have set before.

Advantage: always surveys the temperature not valve position.

Movement dynamics based on temperature and survaillance time:

The installing and the setup should be done by a professional with the appropriate electrical knowledge.

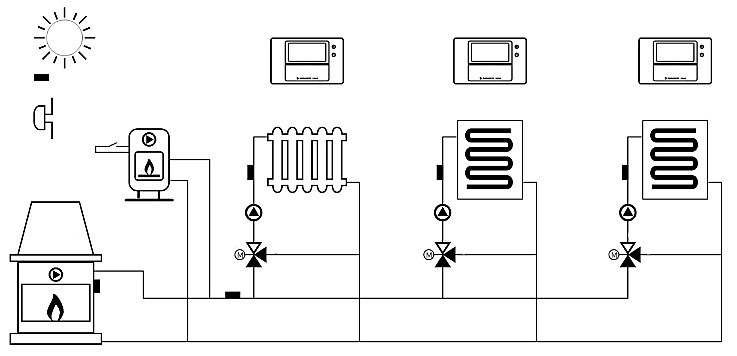

UNI3 is a universal controller designed to control the heating system equipped with:

- Three independent CH heating zones with mixing valves (e.g. for floor heating, radiator heating)

- Main heating source – with its own controller, e.g. gas-fired boiler

- Additional heating source – e.g. solid fuel boiler, fireplace

CH zones

- Independent setting of temperature and weather curve for each zone

- Independent control of each zone with room thermostat and weekly schedule

- Possibility to turn off the mixer control

- Possibility to turn the zone off

- Manual or automatic switch of summer / winter season – possible setting of starting and ending dates of

the heating period

- Selection of a zone operating mode: by turning the pump on or off or by decreasing the temperature with a mixing valve with the pump turned on permanently

- Cooperation with the floor heating distributors

- Possibility to turn on the frost protection mode

- Alarm of exceeding the maximum allowable temperature

Additional heating source zone

- Utilizing the heat generated in an additional heating source (e.g. a fireplace)

- Automatic switch-off of the main heating source when the additional one is operating

- Adjustable shutdown temperature

- Alarm indication

Communication

- Possibility to combine several UNI3 and UNI2 controllers

- Common weather sensor

- Common supply temperature sensor

- Common (one) boiler control output

- Common (one) control output for audible alarm

UNI3 example system:

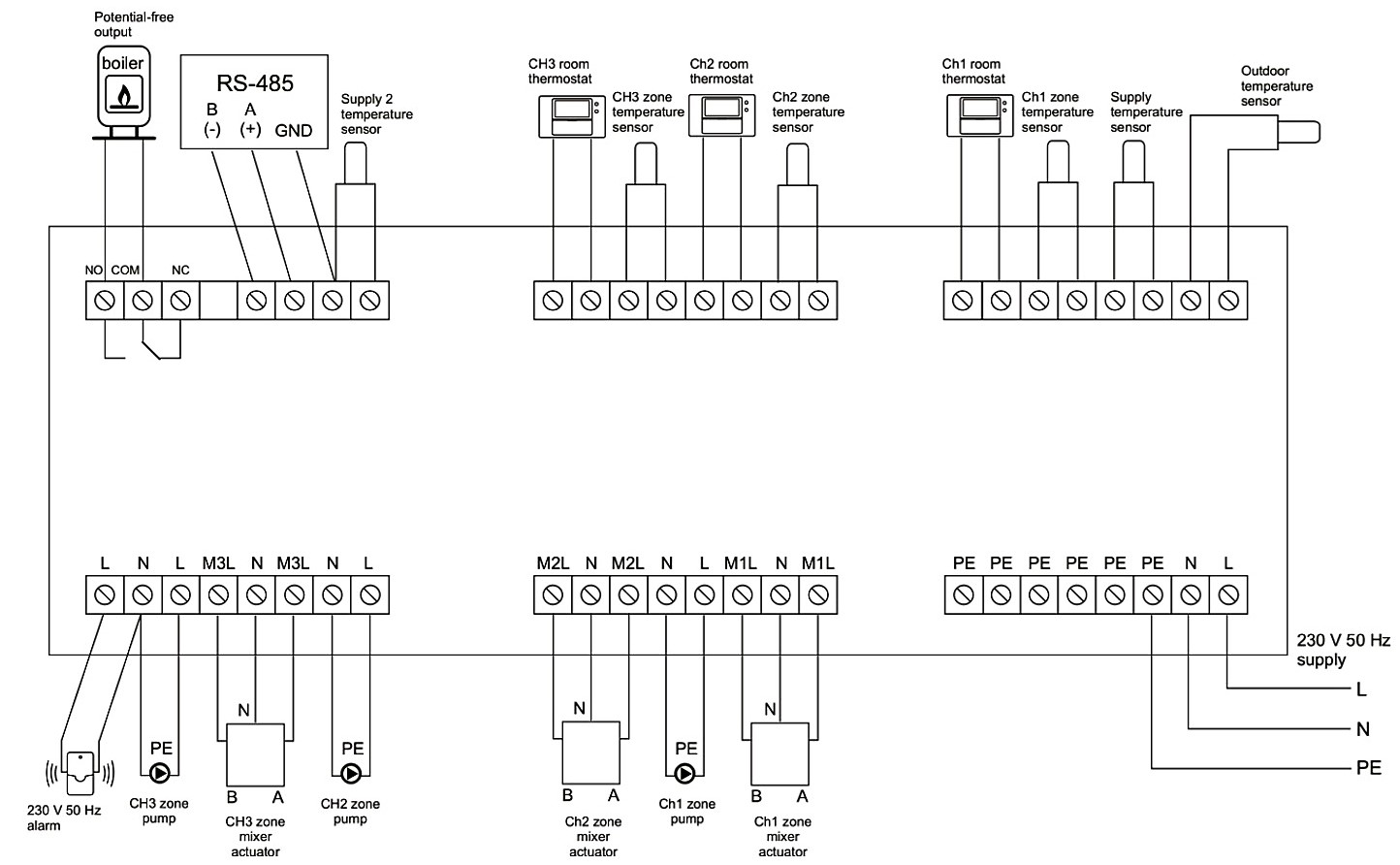

UNI3 controller wiring:

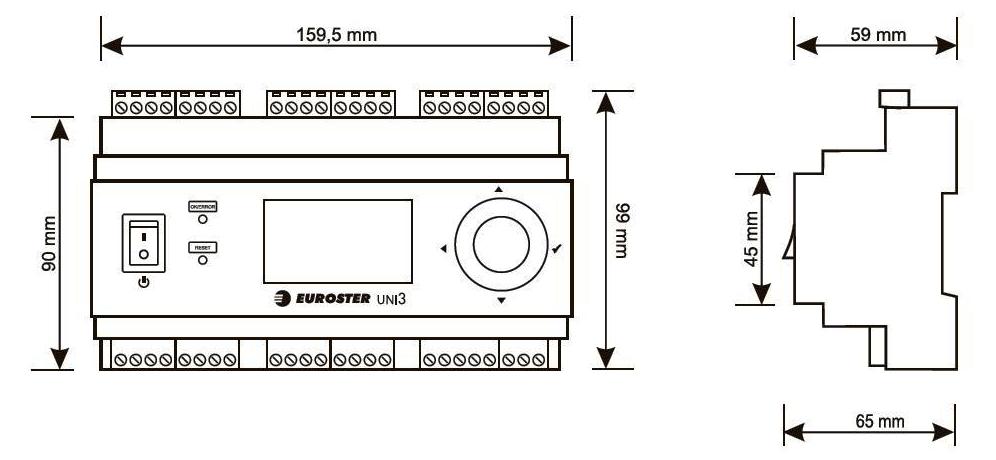

UNI2 sizes:

Length of sensors included int he set:

1. Outdoor temperature sensor (5m)

2. Powertemperature sensor (1,5m)

3. CH1 circuit temperature sensor (1,5m)

4. CH2 circuit temperature sensor (1,5m)

5. CH3 circuit temperature sensor (1,5m)

6. Additional heat source temperature sensor (1,5m)

Utility functions

- Control of a gas-fired boiler or other heat emitting device with a voltage-free output (no/nc relay contacts)

- Utilizing the heat generated in an additional heating source (fireplace, solid fuel boiler)

- Alarm output (for connecting a 230 V 50 Hz indicator)

- Event log (the controller stores 100 last alarms or irregular situations)

- Interface in: Polish, English, German, Czech, Russian, Hungarian

- Possibility to test each output independently

- Overheating protection for each zone

- Overheating protection for supply

- Cooperation with systems with high supply temperature (up to 110°C) – upon customer request

- Frost protection

- Anti-Stop algorithm – protection of pumps and valves against seizure

Main screen

- The following information is shown on the main screen:

- Zone temperatures: current and preset (e.g. calculated with a weather-based algorithm)

- Active devices (pump, mixer, boiler)

- Controller status (anti-stop, disinfection, heating season: WINTER/SUMMER and others)

- Time and date

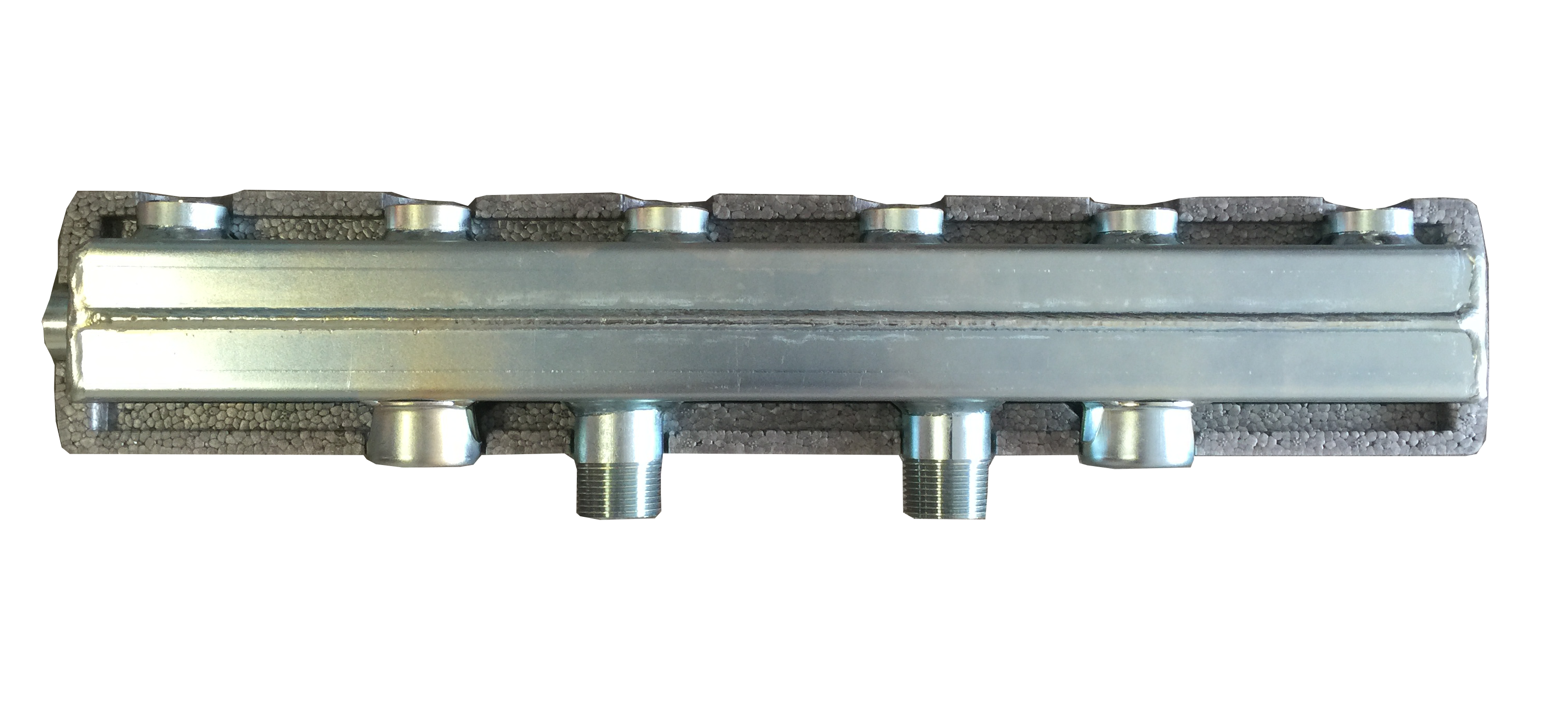

3-way insulated distributor 3/4"

Maximum flow rate up to 2m3/h, 50kW (Δt20K)

max. 6bar.

Connection for pump units: ¾”

Connection for buffer tank: 1”

Insulation box section size: 100x100x540mm

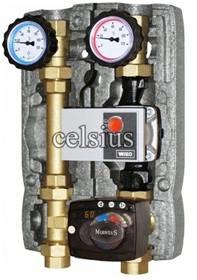

Pump unit with electronic mixing valve

Heating circuit supplier pump unit

Advangates:

- Space-saving, compact design

- Insulated, aesthetic

- Quick and easy assembling

- Mechanic friend therefore is more economical to build up

- Plannable mechanic costs

- Adjustable heating water temperature per heating circuit

- Reasonable price/value rate

- Long lifetime for the best quality components

Pump unit with servomotor mixing valve 3/4”

2-WAY PUMP UNIT WITH 3-WAY MIXING VALVE WITH BUILT-IN BY-PASS 0-50%

DN20 pump units can be connected to heating systems with powers up to 33kW, with a very

low energy consumption assured by high efficiency synchronous circulating pumps.

EPP insulation box (Measurements: 180x302x142 mm).

Centre distance 90 mm.

Especially suitable to manage medium-low powers in small rooms,

thanks to its centre distance of only 90 mm.

For power up to 33 kW (with Δt 15 K).

Maximum flow 1900 l/h.

Kvs value: 5.5

For an accurate measuring or for higher flows, please refer to the curves shown in the next page.

The unit for 1/2” (130 mm) circulating pumps consists of:

Supply:

- Connection.

- 3-way mixing valve with adjustable by-pass. Through the bypass

(adjustable from the front part) it is possible to mix on the

supply line a quantity of water coming back from the return

line of the system, from 0 up to 50%.

- High efficiency synchronous pre-wired circulating pump (for the models that include it).

- Flanged ball valve supplied with in-handle thermometer (coded red, range 0°C-120°C).

Return:

- VFlanged ball valve with non return valve 20 mbar (which can be excluded by rotating the handle by 45°)

supplied with in-handle thermometer (coded blue; 0°C-120°C).

- “T” Connection for mixing valve.

- Connection.

|

Approximate data for applications in low and medium temperature heating systems

|

| ∆t |

Approximate power and flow of the installation

|

Recommended circulating pump

|

Residual lifting power

|

Approximate surface of the underfloor heating system

|

|

8 K

|

12 kW - 1300 l/h

|

Wilo Yonos Para RS 15/6

|

4,5 mH20

|

Up to 100 m²

|

|

8 K

|

17 kW - 1900 l/h

|

Wilo Yonos Para RS 15/7,5

|

5 mH20

|

Up to 170 m²

|

|

15 K

|

23 kW - 1300 l/h

|

Wilo Yonos Para RS 15/6

|

4,5 mH20

|

-

|

|

15 K

|

33 kW - 1900 l/h

|

Wilo Yonos Para RS 15/7,5

|

5 mH20

|

-

|

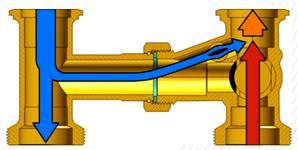

Working principle

During the regular working process, with the mixer completely closed on the recy cling for example, a part of the fluid is aspirated from the pump all along the by-pass line. This quantity of fluid (narrow blue arrow) represents 50% of the capacity of the mixer (red arrow). As a result, one has a very high delivery capacity and a reduced temperature.

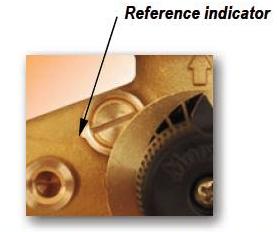

Servomotor TRM20:

3 points servomotor for mixing valve, bidirectional,

reversible.

Operating range of 90°, 230V, 105 s., torque 2 Nm. IP40.