Boiler capable of accommodating CELSIUS Combi 45-50 automatic pellet burning equipment

Power: 50 kW

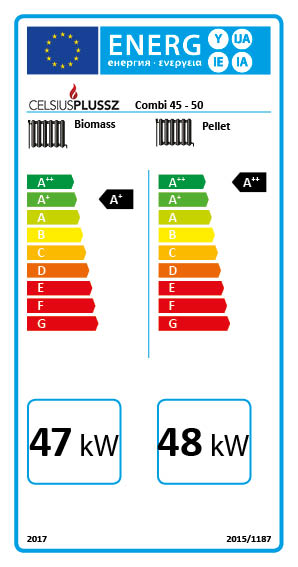

The newest product from Celsius Plus Kft. is the Celsius Combi boiler family.

The boilers are suitable for burning non-woody biomass and wood pellets in automatic mode. Thanks to their special design, outstanding efficiency can be achieved with both fuels. The system can be assembled easily and quickly. For mixed combustion, the large combustion door provides an advantage. The wide cleaning door makes boiler cleaning more convenient. The 5 cm thick insulation and multi-layer steel door contribute to higher efficiency.

The automatic pellet burner can be easily and quickly connected to the boiler using a specially designed connection door. With pellet burning, the comfort of automated technology can be enjoyed:

- Automatic on and off

- Fire control and modulation (5 different power levels)

- Ability to store firing parameters for four different pellet qualities

- Longer maintenance intervals

- Faster cleaning

The boilers comply with the harmonized standard MSZ EN 303-5/2013, as certified by TÜV SÜD. According to this standard, the boilers achieved Class 3 for mixed combustion and Class 5 for pellet combustion, which is the highest classification according to EU norms.

System accessories:

- Celsius Combi Boiler

- Oxi EVO 52C Pellet burner and dosing system (click HERE for a detailed description)

- Pellet storage tank

- Pellet burner connection door

- Fire grates for mixed and pellet firing

- Electrical cables for connection, heat sensor

- Room thermostat connector

- Boiler filling drain tap

| TECHNICAL SPECIFICATIONS |

| Modul |

Combi 45 - 50 |

| Firing door size (mm) |

310*385 |

| Maximum heat output (kW) solid/pellet |

47/48 |

| Heating-system dependant heatable air-space(m3) |

700-1300 |

| Fuel-dependant efficiency (%) solid/pellet |

84/94 |

| Heating water connection (") |

2 |

| Uptake connection (mm) |

160 |

| Height (mm) |

1160 |

| Width (mm) |

665 |

| Depth (mm) |

775 |

| Weight (kg) |

315 |

| Water volume (l) |

113 |

| Max. operating pressure (bar) |

2 |

| Max. operating temperature (°C) |

90 |

| Test pressure (bar) |

4 |

| Draught demand (g/s) |

49,3 |

| Firebox size (mm) (height*width*depth) |

460*470*600

|

|

Parameter

|

Model

|

|

EC14

|

EC16

|

EC18

|

|

Nominal power, kW

|

26

|

52

|

82

|

|

Minimum power, kW

|

18

|

37

|

67

|

|

Supply voltage, V/Hz

|

230/50

|

|

Average energy consumption, W

|

48

|

|

Ignition power, W

|

407

|

|

Total length, mm

|

601

|

636

|

671

|

|

Total height, mm (without elbow)

|

341

|

|

Total width, mm

|

312

|

|

Combustion chamber height, mm

|

169

|

190

|

210

|

|

The width of the combustion chamber, mm

|

201

|

221

|

241

|

|

Combustion efficiency

|

>98%

|

|

Available boiler efficiency

|

<92%

|

|

Smooth power modulation

|

Yes

|

|

Complete with fuel spiral conveyor belt (1.5 m)

|

Yes (Ø70 mm)

|

|

Complete with a fusible corrugated hose

|

Yes (1m)

|

|

Under peak pressure in the boiler, Pa

|

20

|

|

EVO series burner weight, kg

|

22

|

25

|

29

|

|

Fuel spiral conveyor belt weight, kg (1.5 m)

|

11

|

|

Minimum power, kW

|

18

|

37

|

67

|

|

Supply voltage, V/Hz

|

230/50

|

|

Average energy consumption, W

|

48

|

|

Ignition power, W

|

407

|

|

Total length, mm

|

601

|

636

|

671

|

|

Total height, mm (without elbow)

|

341

|

|

Total width, mm

|

273

|

|

Combustion chamber height, mm

|

139

|

160

|

180

|

|

The width of the combustion chamber, mm

|

142

|

162

|

182

|

|

Combustion efficiency

|

>98%

|

|

Available boiler efficiency

|

<92%

|

|

Smooth power modulation

|

Yes

|

|

Complete with fuel spiral conveyor belt (1.5 m)

|

Yes (Ø70 mm)

|

|

Complete with meltable corrugated hose

|

Yes (1m)

|

|

Under peak pressure in the boiler, Pa

|

20

|

|

EVO series burner weight, kg

|

18

|

21

|

24

|

|

Fuel spiral conveyor belt weight, kg (1.5 m)

|

11

|