*(It need to check the boiler condition annually and every non eletric part annually.)

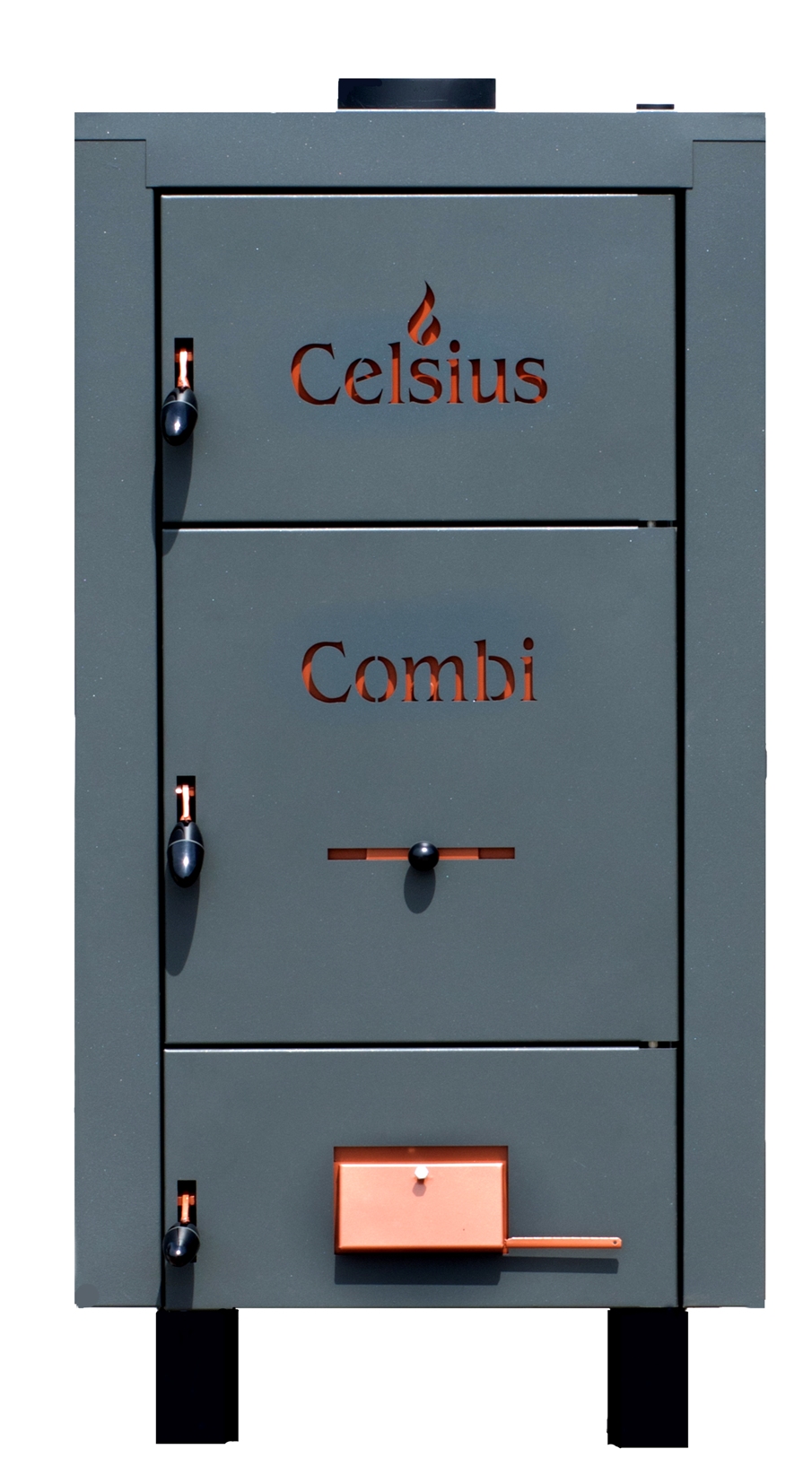

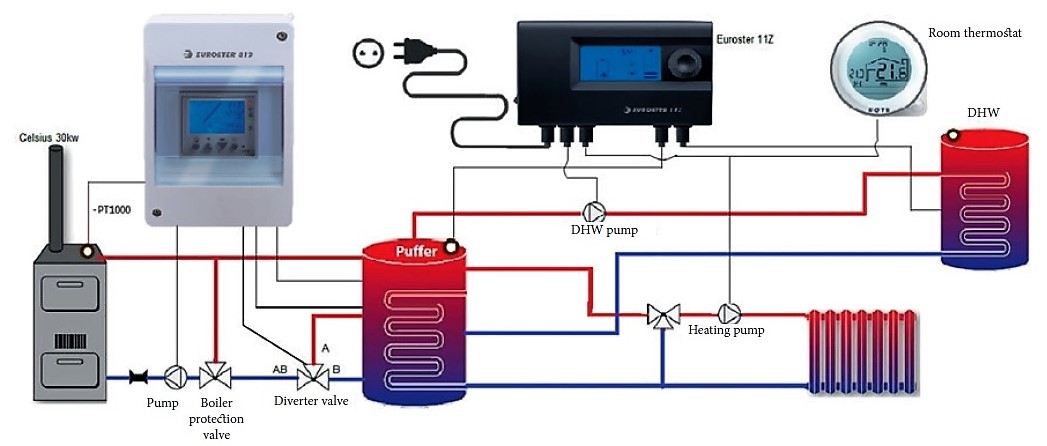

Celsius Combi boiler

With pellet adapter door

The Celsius Combi Boiler is our most up to date boiler.

Celsius Combi boilers were developed to operate with either dry wood or wood pellet (DIN+ quality, 6 mm diameter thick). Its structure is similar to that of a traditional wood burning boiler, however, its operation is a lot more economical with the use of highly efficient equipment. The boiler requires minimum maintenance and will continue to meet your heating requirements over its long lifetime. The boiler can be connected to any kind of central heating system, from radiator to floor heating.

The Celsius Combi Boiler with Wood Pellet burner is efficient and convenient because of:

- Automatic turn on and turn off switching

- Keeping fire and modulation (5 performance levels)

- Increased savings due to possibility of 4 different pellet quality parameters.

- Faster cleaning

These boilers are suitable for burning wood and in auto mode Wood Pellets may also be used. Thanks to its special design the boiler can utilize both fuels with outstanding efficiency. Celsius boilers are suitable for gravity or pump controlled heating systems for family houses, workshops, various farm houses, agricultural halls, institutions and greenhouses. Celsius solid fuel burning boilers have different models which are sized by heat output to meet your individual requirements.

Accessories:

- Fire grates (grills)

- Wooden pellet burner adapter door

- Filling/draining trap

|

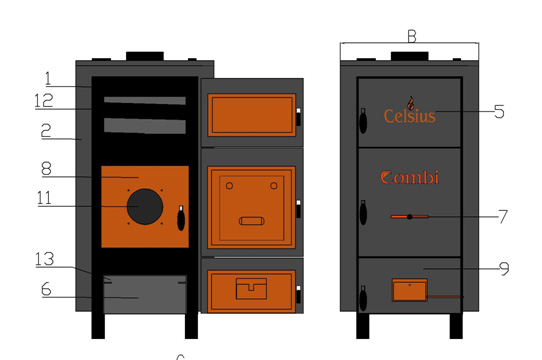

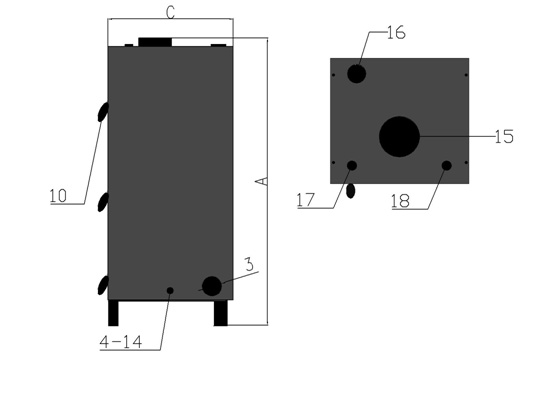

Mark

|

Description

|

|

A

|

Height of boiler

|

|

B

|

Width of boiler

|

|

C

|

Depth of boiler

|

|

1

|

Boiler body

|

|

2

|

Exterior cover

|

|

3

|

Return water connection

|

|

4

|

Filling/draining tap connection

|

|

5

|

Upper door

|

|

6

|

Ash pan

|

|

7

|

Firing door (wood burning)

|

|

8

|

Pellet burner adapter door

|

|

9

|

Ash removal door (primary draught regulator)

|

|

10

|

Door opening handle

|

|

11

|

Firebox

|

|

12

|

Heat exchangers

|

| 13 |

Grate (grill)

|

| 14 |

Safety valve or pressure guage

|

| 15 |

Uptake connection

|

| 16 |

Forward water connection

|

| 17 |

Thermometer connection

|

| 18 |

Automatic draugh regulator connection

|

| TECHNICAL SPECIFICATIONS |

| Modul |

Combi 29 - 34 |

| Firing door size (mm) |

310*330 |

| Maximum heat output (kW) wood/pellet |

34/34 |

| Heating-system dependant heatable air-space(m3) |

350-550 |

| Fuel-dependant efficiency (%) wood/pellet |

82/92 |

| Heating water connection (") |

2 |

| Uptake connection (mm) |

150 |

| Height (mm) |

1140 |

| Width (mm) |

555 |

| Depth (mm) |

625 |

| Weight (kg) |

205 |

| Water volume (l) |

82 |

| Max. operating pressure (bar) |

2 |

| Max. operating temperature (°C) |

90 |

| Test pressure (bar) |

4 |

| Draught demand (g/s) |

39,6 |

| Firebox size (mm) (height*width*depth) |

520*330*460

|

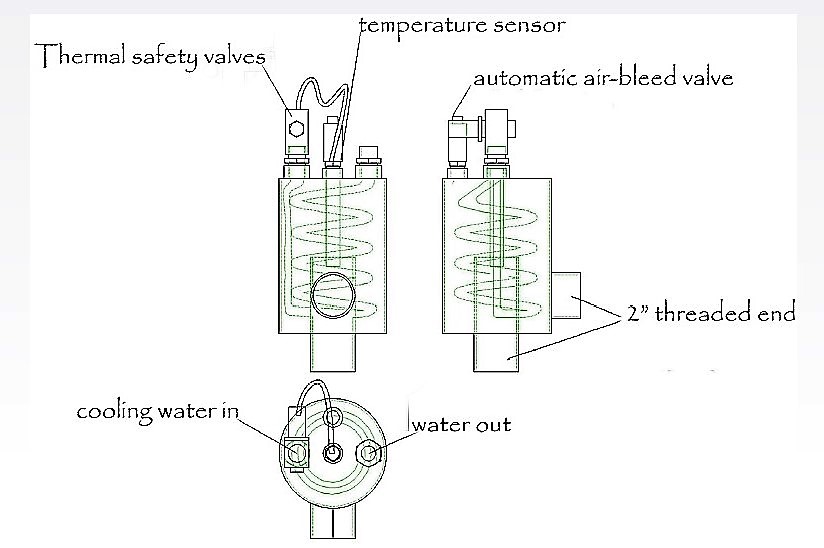

Celsius safety heat exchanger

It protects the boiler and environment if the boiler is overloaded and the heating system can not heat distribute (There is not buffer tank and irregular usage).

Content of equipment:

- Celsius safety heat exchanger

- Vent valve

- Thermostatic security valve (opening temperature 98°C)

- Pressure security valve (2bar)

Applicable to the following boiler types:

Celsius classic, Celsius C and Celsius Combi boiler

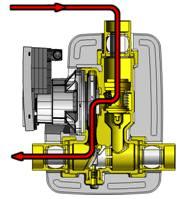

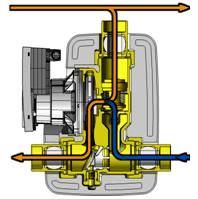

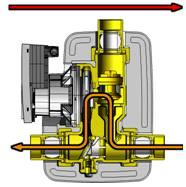

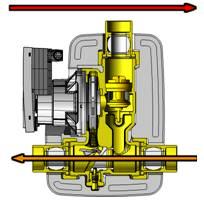

Celsius anticondesing recycling pump unit to 56 kW

Properties:

- Complete assembled units.

- Space-saving, it has minimal space requirement due to compact design.

- Insulated, the assembled units have an insulating cover.

Application:

The anti-condensing pump unit can be connected directly to the solid heating source in the heating system or to the buffer tank without any additional device. The pump unit is housed in a compact insulation box which includes the circulation pump, the anti-condensing thermostatic valve, the on/off natural circulation clapet valve, the isolating valves and thermometers. It automatically adjusts the returning water to the heating source at the selected thermostat value setting.

Technical features:

- Synchronous high efficiency Wilo Yonos Para RS/7-RKC circulating pump with progressive speed control.

- Max. working pressure 10 bar

- Max. temperature 100°C

- Setting temperature 55°C

- Natural circulation clapet valve: with external control, it can be set on or off according to the type of installation.

- Temperature thermometers: 0-120°C.

Nominal opening temperature: setting temperature + 10 K.

The max. usable power up to 80 kW (at Δt 30 K) with synchronous circulating pump Wilo Yonos RS/7-RKC.

Working mode:

Starting the installation (boiler warming up):

After the starting of the boiler, the thermic valve is fully closed towards the user’s return (gate A) and this condition remains until the fluid, warmed up by the heating source, gets the opening temperature of the thermic valve (corresponding to the setting value, f.i. 55°C). During this step the fluid sent by the boiler fully recycles through the by-pass (gate B) and the boiler temperature rises very quickly.

Loading the installation (tank warming up):

Achieving the opening temperature (f.i.55c), gate valve A proportionally starts to open while gate valve B proportionally starts to close. The boiler temperature slowly rises providing energy to the user, however the return temperature will not decrease below the setting temperature (f.i. 55c)

Working installation:

Starting from the condition of point 2, the supply temperature progressively rises up to the full opening of the thermic valve (gate A) and up to the corresponding shutting of by-pass (gate B). This happens at about 10 K more than the opening or setting temperature (therefore in the example in hand, at about 65°C). Now the installation is on working and the supply fluid temperature can rise up to the set value.

Natural circulation:

The natural circulation of fluid through the clapet valve starts as soon as the circulating pump stops and the remaining energy of the heating source is transferred to the water tank. This function starts as a security device, when the pump stops due to blackout or failure, so avoiding that the temperature of the heating source can reach high levels of danger. To turn on the natural circulation function please turn the control screw anti-clockwise.

You can lock the clapet valve any time, turning the screw clockwise (this operation has to be done when the pump is working).

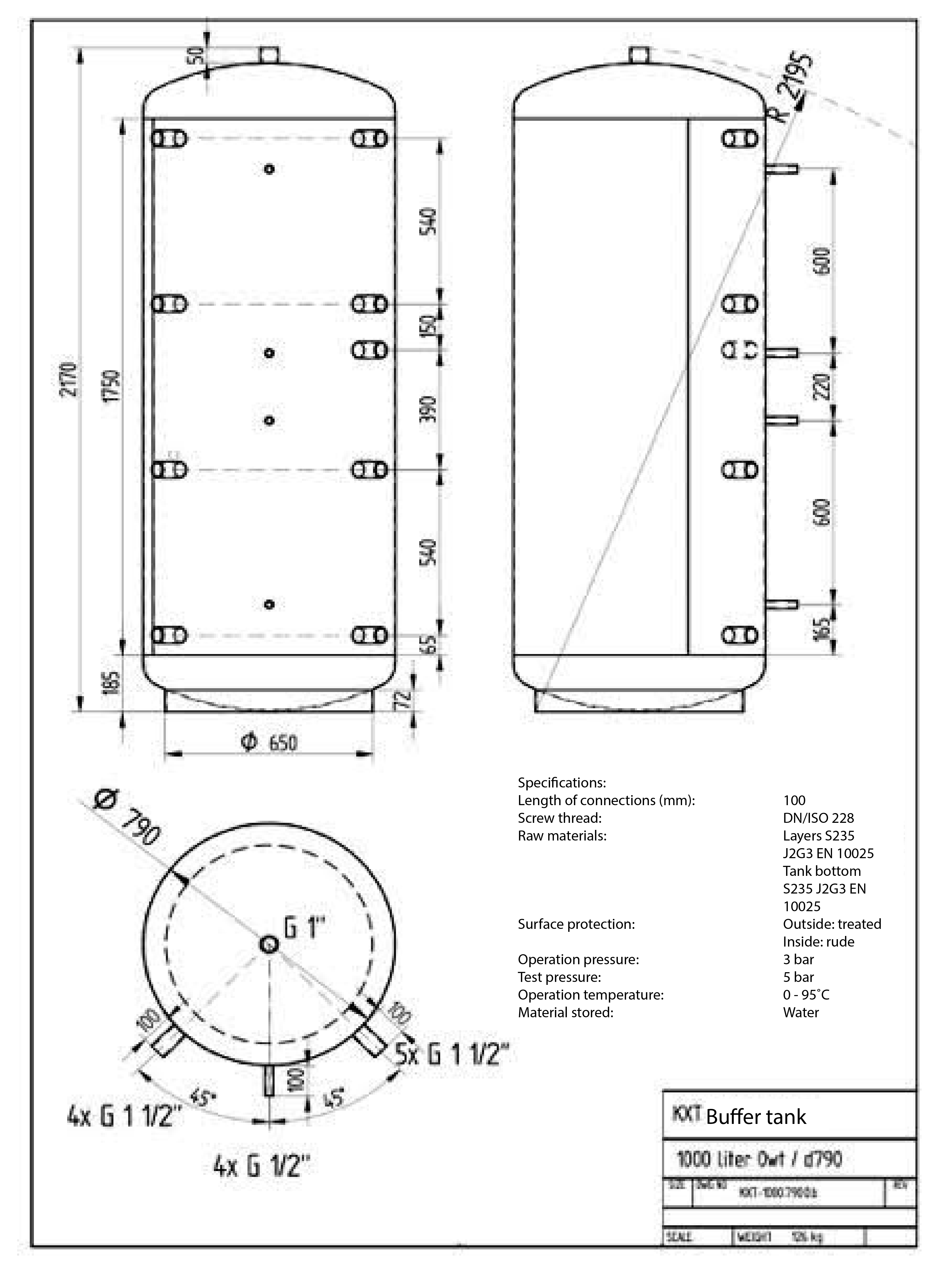

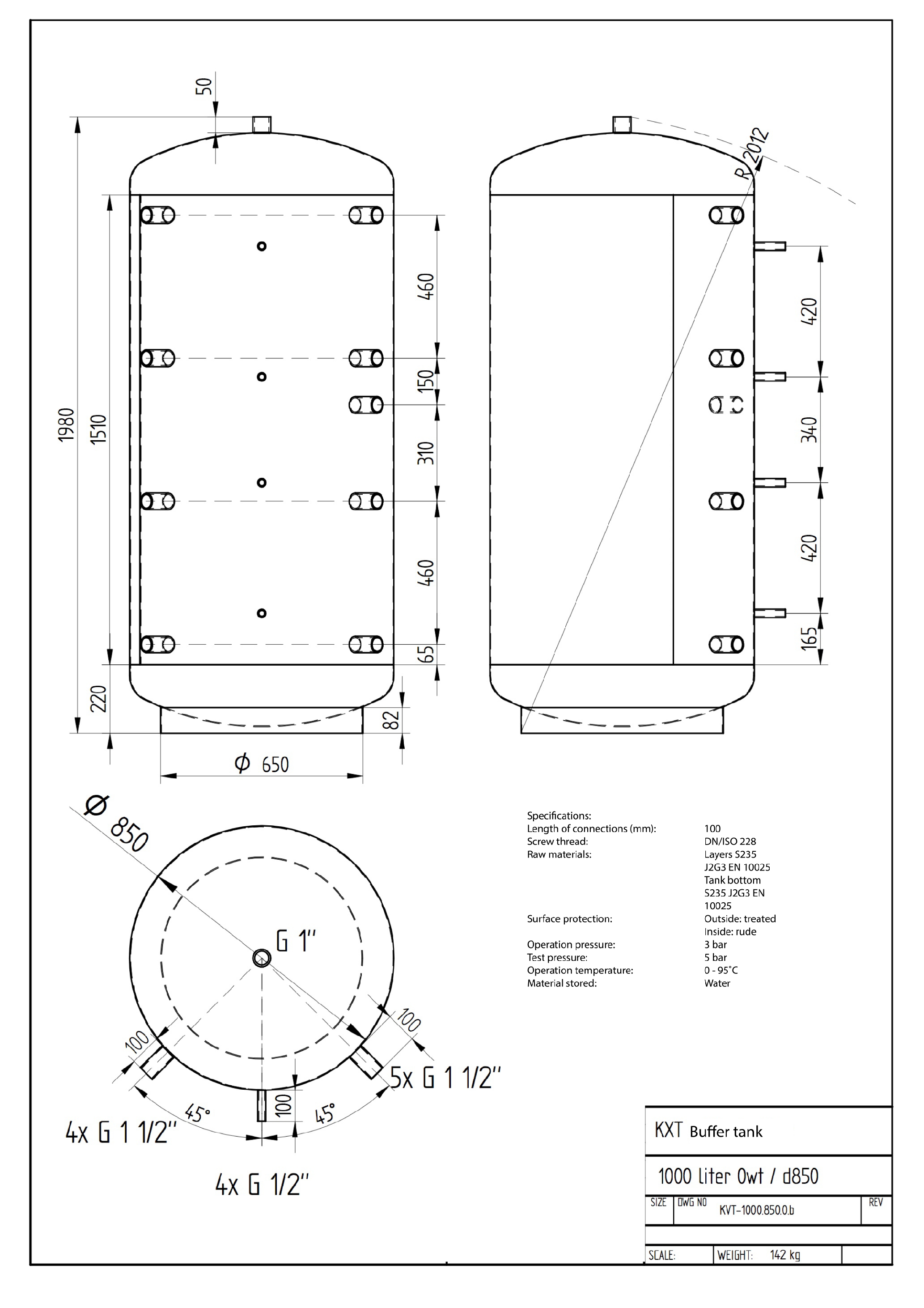

Celsius insulated buffer tank

Celsius buffer tanks:

To maximise the efficiency of a solid fuel heating system a buffer tank should be installed. When the boiler has produced energy to satisfy the heat demand, excess energy produced by fuel in the combustion chamber can be captured and stored in the buffer tank. The exception to this is when using wood pellets, where the pellet burner will automatically stop when the heat demand has been satisfied.

When the heating system have surplus heat ,the buffer tank stores it, therefore the wood boiler doesen't need an automatic draft regulator which ruins the burning efficiency.

Advantages of Celsius insulated buffer tank:

- High quality insulation (C energy rating, EU complaint)

- More economical burning

- Lower pollutant emissions

- Aesthetic design

- Guaranteed continuous heating (for example: It can heat all night)

- Hot domestic water modul can be connected

Sizes:

Shorter version:

Motorized 3-way zone valve

Motorized 3-way zone valve with spring return for closed hydraulic systems.

Technical features:

- Area of use: heating, conditionning and solar thermal (glycol max. 50%).

- Power supply 230 VAC, 50Hz, absorbed power: 6W

- Protection IP22

- Nominal pressure PN10

- Room temperature Max. 60°C

- Fluid temperature: 5÷120°C; short time: 150°C;

- Nominal opening time: 20 s. Springclosing: 6 s.

- Kvs value 12,6

- Without power AB->B

- Weight 1,3 kg/piece

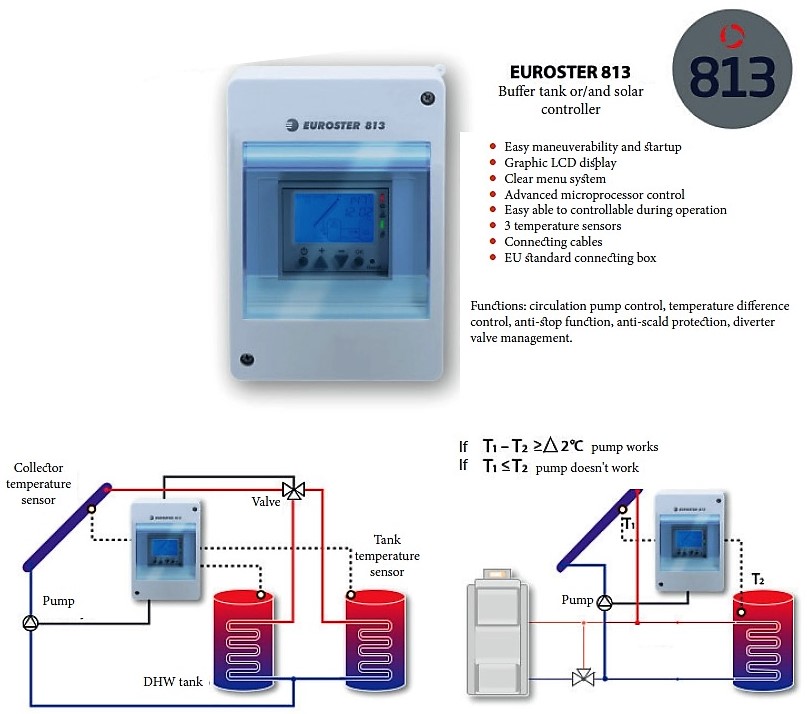

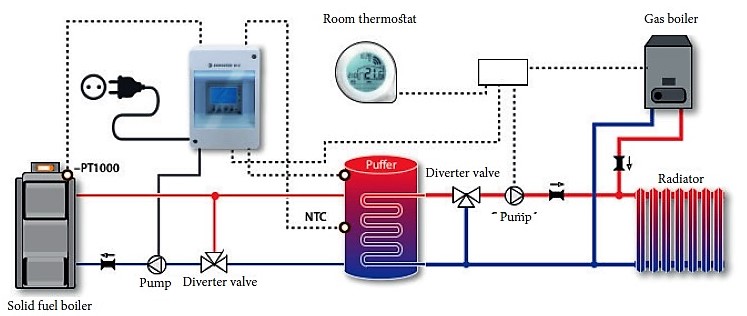

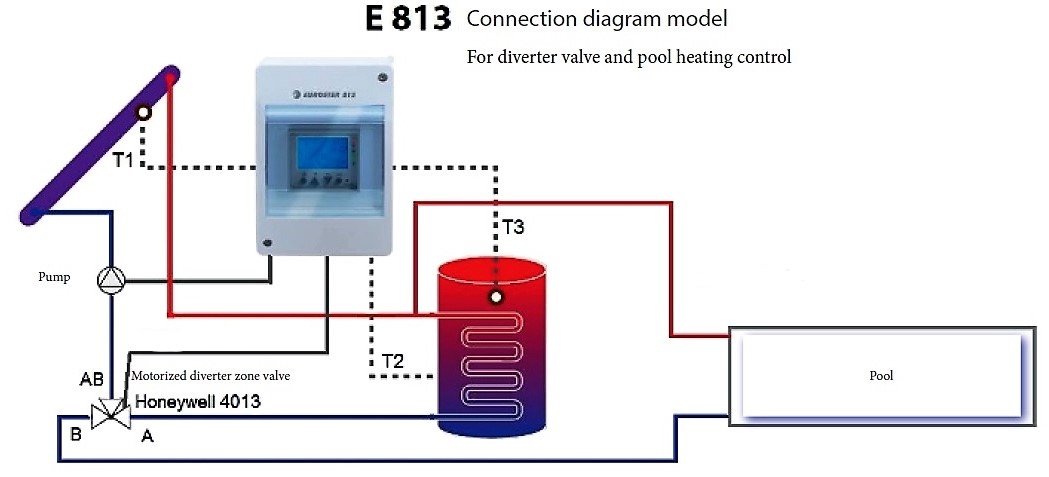

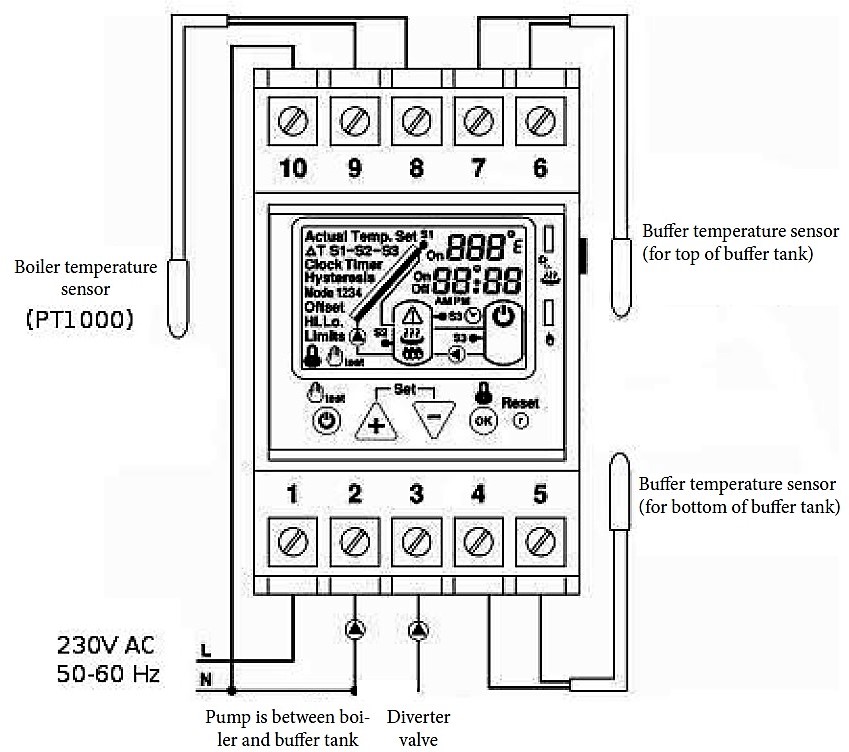

Euroster 813 controller

Operating principle:

The EUROSTER 813 control unit is a universal microprocessor controller with graphical display. The controller is responsible for the pump to operate on the basis of the difference between the set temperatures. It is possible to set up in the control an automatic disinfection function.

The control is responsible to turn on the pump on the basis of the difference between the set temperatures to ensure that the container is warmed by only the surplus heat, thus making energy savings.

The controller has a variety of automatic emergency circuit options.

You can set the emergency value of solar ebullience. There's an automatic vacation mode available, which takes care of cooling the storage to the set value, overheated by the solar system. This mode is important, if the storage is not used on a daily basis and ebullience of the solar panel will be induced. The keyboard of the control unit is lockable in the purpose of protection of your set parameters, which can cause an error.

The controller has a security sensor testing, if sensor sings, it will automatically trigger the pumps, preventing the ebullience. The controller has a sensor calibration mode, which allows you to avoid false temperature measurement by the long lines.

Treatment of controller

The graphics display of the EUROSTER 813 controller makes it easy to set up the controller. The options of setting the controller:

- Pressing the +/- buttons at the same time you can reach the menu.

- Pressing the -/ok buttons at the same time you can lock the keyboard.

- Pressing the +/ok buttons at the same time you can reach the manual mode, pressing the /+ button you can select the manually accessible devices.

After entering the menu you can set the following values:

- time

- disinfection (on/off)

- modes

- maximum emergency starting temperature of collector or boiler

- minimal starting temperature of pump

- maximum temperature of storage

- starting and shutdown temperature of solar delta T

- temperature of storage/hysteresis

- calibration of solar sensor

- calibration of storage sensor

Controller can be applied to:

In the case of Vacuum-tube control plane collector, mixed-fired boilers and buffers.

The pump must not be interrupted by other equipment!

|

Operating voltage

|

230V, 50Hz

|

|

Rated vattage

|

1,6W

|

|

Output load of circuit pump

|

200W

|

|

Emergency starting temp

|

60-190 C

|

|

Min. starting temperature of pump

|

15-40 C

|

|

Storage max. temperature

|

0-100 C

|

|

Delta T pump starting (on)

|

3-20 C

|

|

Delta T pump shutdown

|

1-18 C

|

|

Storage temperature

|

10-100 C

|

|

Storage hysteresis

|

2-20 C

|

|

Protection

|

IP40

|

|

Display

|

LCD

|

Cables and sensors of E 813 controller:

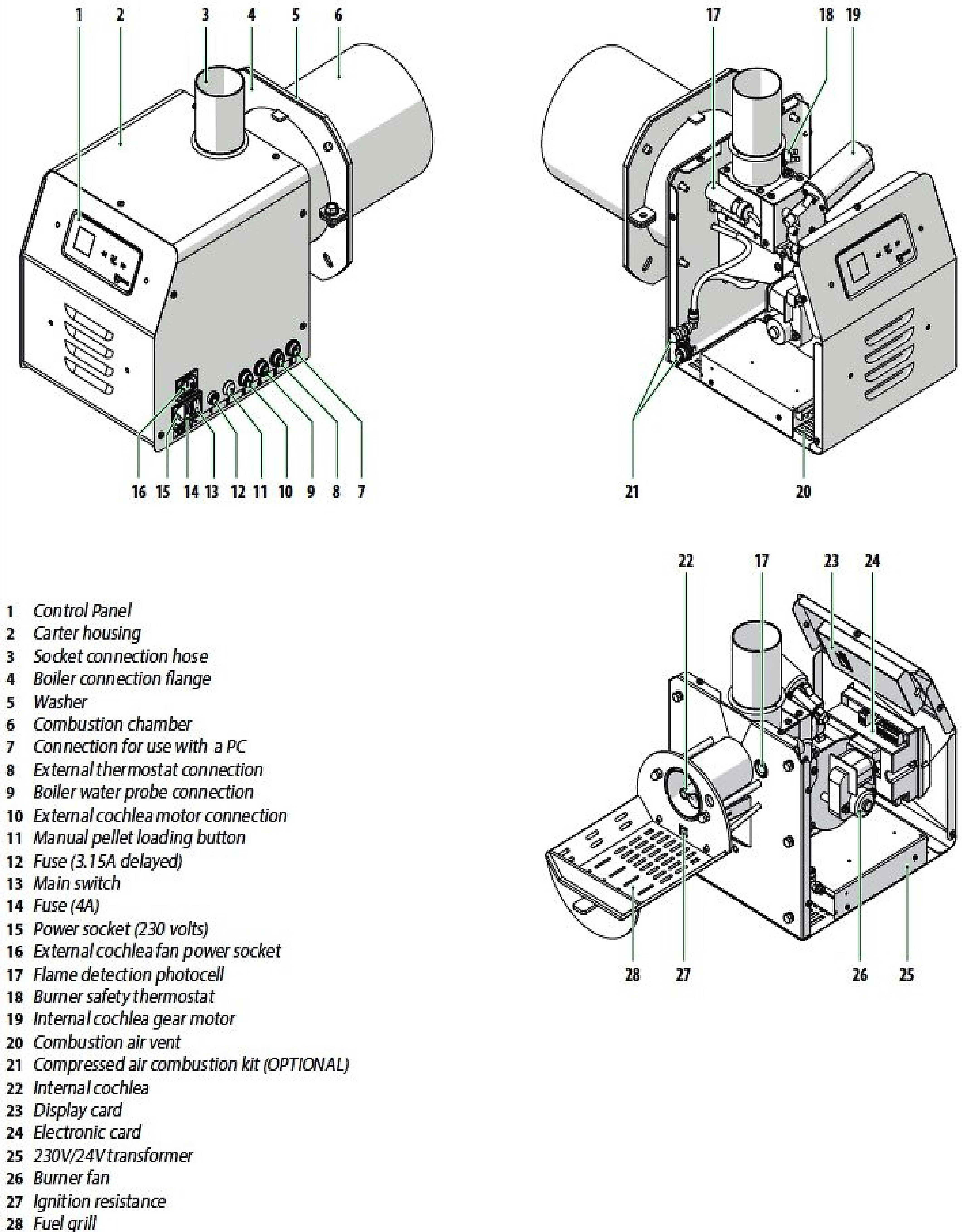

B-Max 30 kW pellet burner equipment

Low-power burner, designed for civilian buildings. It is equipped with a screw pump for loading.

Bmax Technology burners have an innovative self-cleaning system which works on regular intervals: with this system the fuel grid is periodically freed from possible residue that could interfere with the correct combustion or that could induce the suffocation of the flame. In this way, the possibility of turning off the burner and the consequent dispersion of fumes are avoided.

Safety equipment:

- The B-Max 30 kW pellet burner contain safety equipments:

- Burner safety thermostat (for preventing backfire)

- Cutting valve fire (optional) (for preventing backfire)

Accessories:

- Screw (60 mm)

- Pellet tank (200 kg)

- Compressed air kit

Parts of wood pellet burner:

|

Description

|

Measurement

|

B-Max 30 kW

|

|

Burner output

|

kW

|

12÷34

|

|

Electric connection

|

V~Hz

|

230~50

|

|

Average energy consumption

|

W

|

60

|

|

Lighting

|

W

|

170

|

|

Fuse (delayed)

|

A

|

3,15

|

|

Noise level

|

dBA

|

35

|

|

Height of flame

|

mm

|

200

|

|

Min. combustion chamber (height)

|

mm

|

300

|

|

Min. combustion chamber (width)

|

mm

|

300

|

|

Min. combustion chamber (depth)

|

mm

|

350

|

|

Draught demand

|

Pa

|

20

|

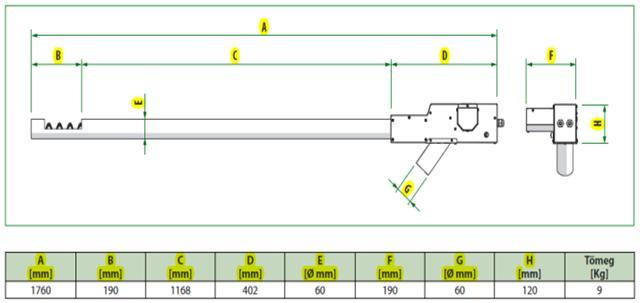

Size and weight of screw feeder:

Wood pellet tank

Celsius wood pellet tank with wheels and cover. Easy to take out pellet.

Sizes:

- Height: 1270 mm

- Width: 820 mm

- Depth: 820 mm

- High width screw feeder: 1900 mm